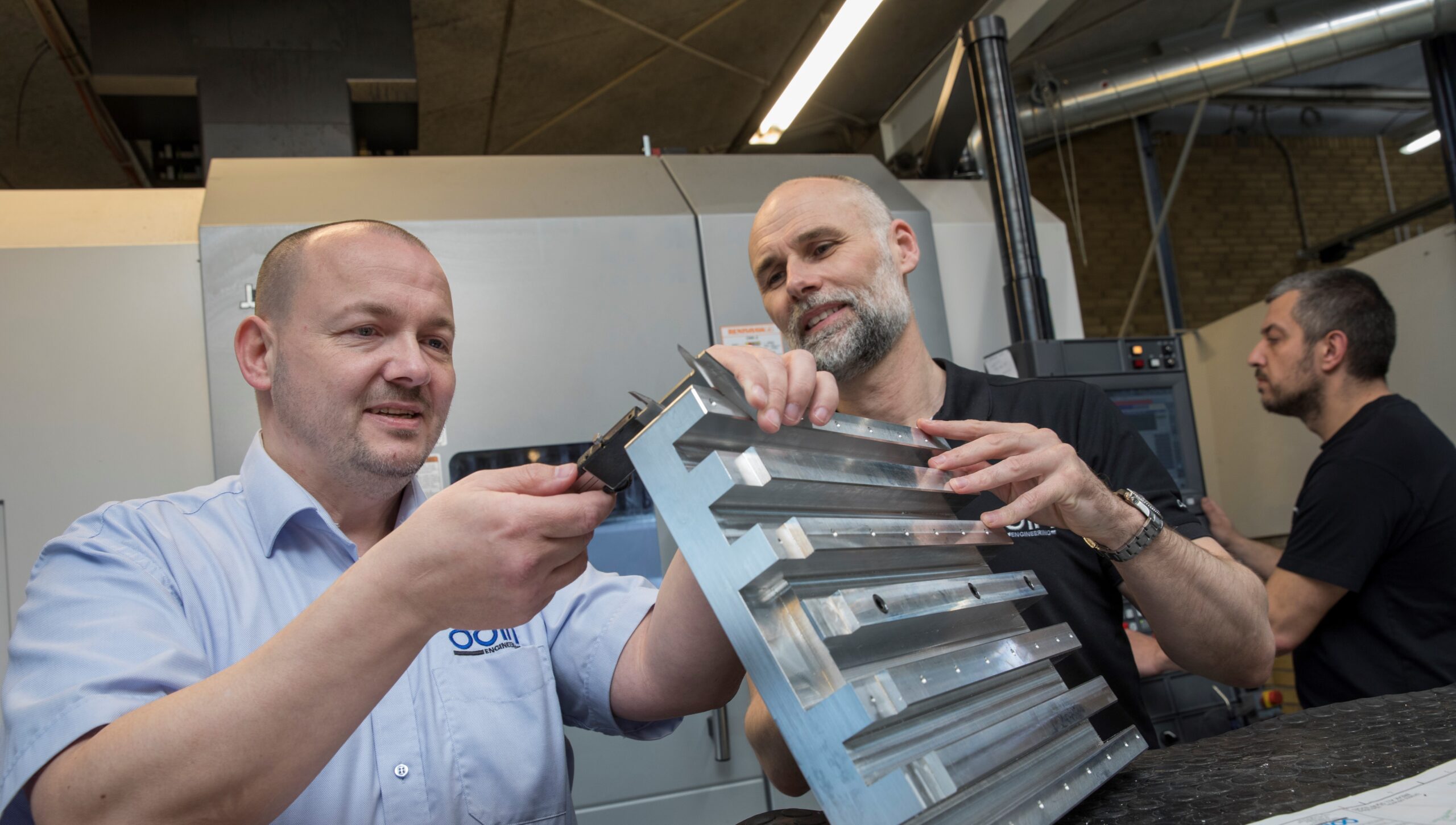

ODIN Engineering’s test centre: There are no limits to the imagination

At ODIN Engineering, we are the indispensable business partner for large industrial companies that need completely unique solutions either in Denmark or around the world. Our test centre is a good example of this.

At the test centre, we have many possibilities to help our customers. We can, for example, develop and test the right solution and special machine, make production of prototypes, set up, test, and fine-tune different production lines or supplement the customer’s own production. There are no limits to the imagination. Just like everything else at ODIN.

ODIN Engineering develops business-critical solutions and special machines for large industrial companies. The machines are built from scratch and tailored to the individual customer’s needs. But ODIN is much more than a specialised machine supplier.

“Our motto is that nothing is impossible, and that approach makes us a special partner for our customers. And it’s not just something we say. ODIN’s test centre is a good example of this,” says our CEO Mads S. Rasmussen.

From idea to production line – from prototype to finished product

The employees at ODIN Engineering go to great lengths to understand the customers’ production processes and strengthen their production and business with well-thought-out and long-lasting technical solutions.

The test centre is a place where the prototypes that ODIN develops can be put into prototype production or actual production. It also provides the possibility to test how the solution and the completely unique new special machines work in practice without interrupting the current production in the customer’s own production. In addition, you can test and plan how to integrate new special machines into an existing production.

“If the customer is not sure of his setup, we’ll find out how the machine can best be included in the existing production, or how a completely new production line is built. Maybe we need to fine-tune the design, we can investigate this together with the customer at the test centre, says Martin Christensen, COO at ODIN Engineering.

Setting up production facilities for prototypes, supplement, and peak time

At the test centre, ODIN Engineering also has the possibility of setting up the customer’s entire

production apparatus. It can be for the production of prototypes or special components that the customer does not want in his own plant. In practice, our customers can set up their very own production lines here at ODIN – they can borrow our employees or train and educate their own. The setups can then be simpler, cheaper, and more labour-intensive than the final solution. In this way, the customer can also get a test or start-up production, which is variable in costs according to the output required. It can be beneficial if you test a product that you do not know if it will break through in the market.

“You can approach us with an idea for a production and nothing else. Then we develop the solution and the machines from scratch, we build them and start the customers’ production. It’s a dedicated approach, where we are total suppliers and close allies with our customers,” says Martin Christensen.

Martin Christensen experiences that it can also be helpful to certain companies that have capacity problems. When collaborating with ODIN, the customers get a development and production environment where they can have a fixed part of the production or concept development. Rather than expanding their own facilities.

Industrial tests and destructive tests

Many industrial companies need to have components tested to ensure that the parts can withstand certain conditions and loads. For this purpose, ODIN Engineering uses its test centre to develop both the specific components to be tested and the unique machine to perform this particular test. Martin Christensen says:

“It can be components that are to be part of a building or other construction. Maybe you need to build a bridge and therefore you want to test some specific types of bolts. In this case, we can make a setup that builds, for example bolts of different kinds, and we can produce a machine that simulates the situations in which the items must work.”

It is important for Martin Christensen to emphasise that the unique solutions that ODIN Engineering develops belong to the customer who has ordered the task. This means that ODIN’s employees are constantly challenged to invent new solutions and, together with customers, develop special machines that do not yet exist. But which fits exactly to the individual customer’s specific needs and challenges.