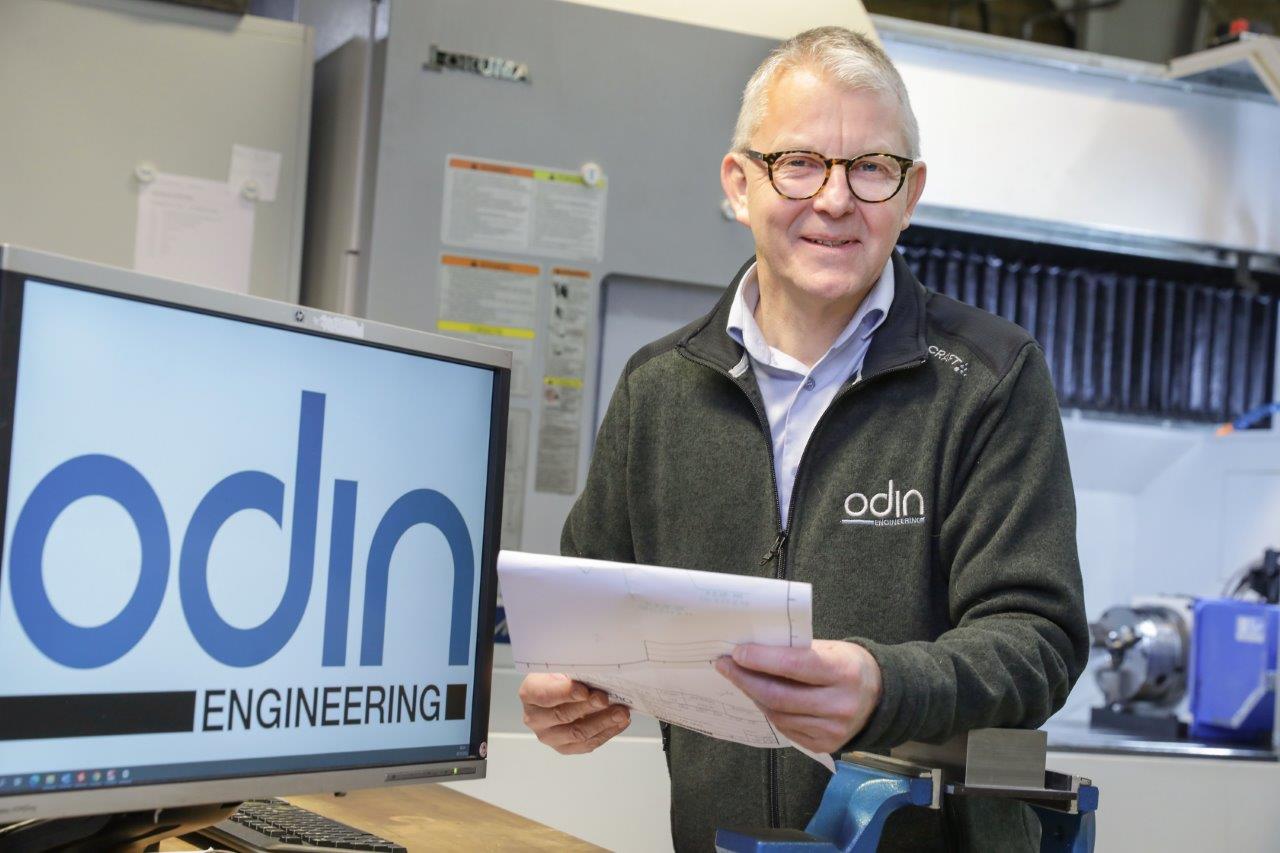

Factory manager Bent Thybo: 34 years of experience in optimising factory production

ODIN Engineering produces unique business-critical solutions for international manufacturing companies. Only one or very few of each special machine is made and it must be efficient, reliable and with delivery at the agreed time. With 34 years of experience from other specialised production companies, Bent Thybo ensures consistency and progress in production.

”The solutions that ODIN develop are completely unique. And the components that make up the special machines are usually specially manufactured by us or by trusted sub-suppliers. Each machine is on an exciting journey here with us – from the first meetings with the customer to the final delivery,” explains Bent Thybo.

The factory manager is responsible for ensuring that production, assembly, and service proceed optimally. Bent Thybo must ensure that our skilled and experienced employees are given the opportunity to contribute their knowledge and ideas, that the machine park is used sensibly, and that the necessary materials and components are available in a timely manner. In addition, the customer must be able to follow the process of their particular solution and have it delivered at the agreed time. Furthermore, a business-critical special machine with an uptime of close to 100 percent.

Great ingenuity and commitment

”I started at ODIN in May 2022 and have felt comfortable from the start. Here, I surround myself with some very inventive, skilled, and committed colleagues,” says Bent Thybo.

”It pleases me that we’re not satisfied with only talking about involving all employees. At ODIN, we actually do. We’ve so-called cabin meetings – inspired by the Sirius Patrol’s way of working,” he says. Bent Thybo is convinced that the cabin meetings are an important factor when it comes to retaining and motivating talented employees. In the cabin, you empty your backpack and talk about strengths, challenges, and problems. Another factor is the work itself:

”At ODIN, it’s a necessity to think outside the box, and we use many resources to find the best solutions. Every time. We do a lot to inspire the talented employees to be part of this creative work,” says Bent Thybo.

The prerequisite for optimising factory production

Bent Thybo has 34 years of experience from jobs in production management in large and small production companies. As a newly qualified production engineer, he began the first four years of his career in 1988 as head of production preparation at Aasted in Farum.

”I have a lot of experience when it comes to implementing production processes and using ERP systems to create an overview and the opportunity to make good decisions. ODIN would like to continue to develop and refine its processes continuously. We therefore analyse in more detail and introduce a few more systems and processes that support the employees,” says Bent Thybo.

The third generation Rasmussen has taken the wheel at ODIN Engineering

”With our customers, it’s owner-manager Mads S. Rasmussen who represents the company. ODIN has existed as a family business for three generations and for more than 60 years,” says Bent Thybo adding:

”It’s a force to have Mads at the factory. After all, he grew up here and knows the customers very well, and for him it’s also important that there are skilled people at ODIN to hand over to and who make things happen in practice. Personally, I’m very happy and humbled to be given that opportunity.”

An active native of Funen

Bent Thybo turns 60 in December. He lives in Årslev on Funen with his wife. They have two adult boys who have followed in their father’s footsteps as engineers, and an 18-year-old daughter who lives at home. Bent enjoys active holidays. Skiing in the winter and sailing in the summer in both Denmark and Greece, where the family has shares in two boats. He keeps fit by, among other things, running and cycling and also spends his free time with his family and a large circle of friends.