As a full-line supplier, ODIN Engineering has a wide range of quality equipment in our machinery, forging and surface treatment departments.

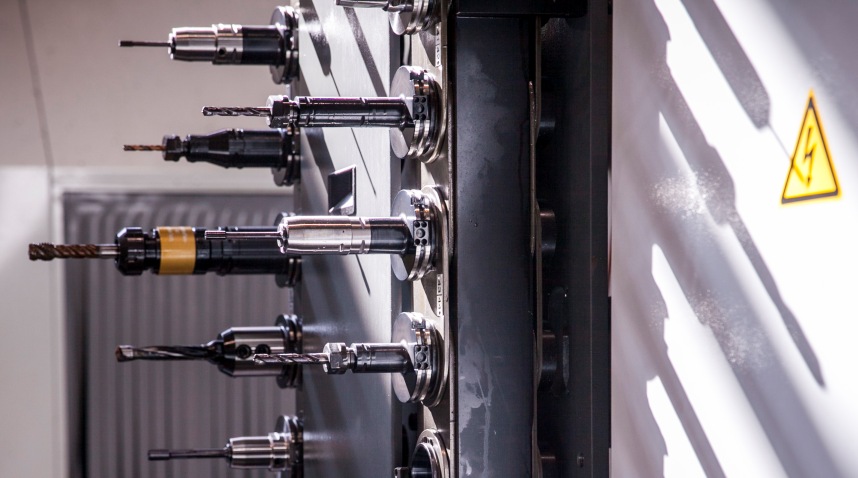

Machinery department

- CNC milling machine, full 5-axis

Z=695/800 Y=750 X=2,600/2,030 – 230 tools - 2 CNC machining centres

Z = 640 Y = 500 X = 1,000 – 35 tools

Z = 640 Y = 660 X = 1.500 – 32 tools - Horizontal and vertical millers

Z = 3,155 Y = 1,200 X = 8,000 Roundtable Ø 800 horizontal and vertical 45 ° automatic head - CNC lathe, Ø 420 x 1,500

- Laser cutter 1,500 x 3,000 x 15 with pallet changer

- Press brake, CNC bending and edge bending, 3,050 x 15, 135 tonnes press capacity

All machines without numerical controls are equipped with digital rulers. Machining can be carried out in all types of construction material. The list is not exhaustive.

Forging department

- Shearing machine 4 x 3,000

- Edge bending machine

- Welding machines for all types of welding

- Crane capacity: 3.2 tonnes

- Forging in steel, stainless steel, aluminium, etc.

Surface treatment

- 50 m2 heated paint shop.

Assembly

ODIN Engineering has modern 3D measuring equipment, for example the measuring arm Hexagon Romer Absolute Arm 7530 with a volumetric accuracy of +/-0.073 mm within a radius of 1.5 metres.

- 2 x 800 m2 assembly shops

- 2 x 10 tonnes crane capacity

- Hydraulic assembly

- Electrical assembly

- Workshop for producing electrical panels